Metal Plank Ceiling

Combining modern aesthetics with a refined look, the Metal Plank Ceiling introduces a unique sense of style to interior spaces. Its strengths lie in the fusion of functionality and visual appeal, providing a durable solution for various settings. The superior properties of metal make it an excellent choice for a range of commercial and residential environments. Not only does it offer exceptional durability and longevity, but it also resists dampness, corrosion, and other environmental factors.

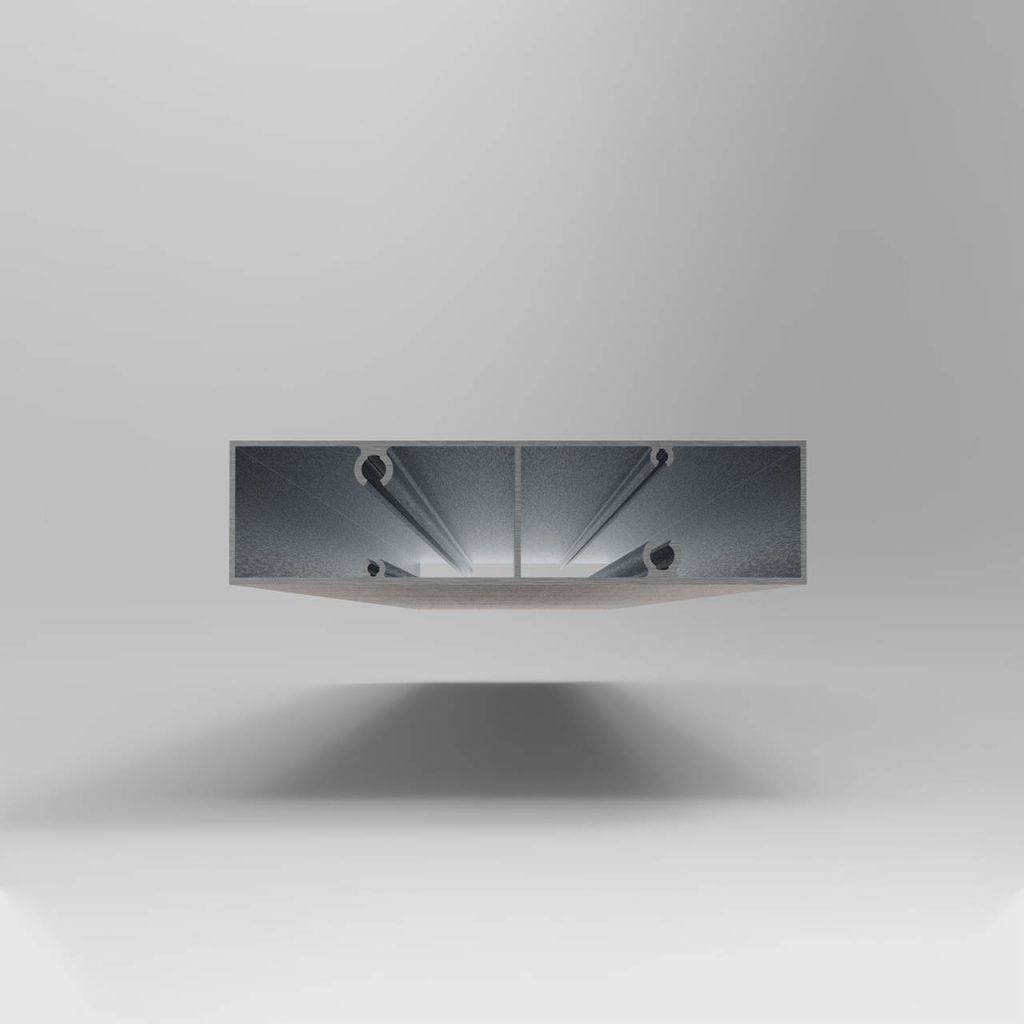

SEAMLESS INTEGRATION WITH CONCEALED SUPPORT

Concealed Suspension Svstem

You can attach windows to the vehicle using panels and special cariers or spring T-bars, Because this method covers the entire grid,the celing loks smoth and whole.

Secure & Stable Fit

The dip system connects every panel securel, so they willnot sag or shit. This is why it works bestin setings that experience a lot of vbration, movement, or airfow

Access & Maintenance

Panels are safe on the vehicle, but can be taken off night away with the right too. Accesto plenum spaces is now faster and easier for anvone working on electriditv

Edge Trims & Wall Angles

Edge trims of panels are used to neatly finish the space between the wal and the celing: They also help hold ceiing panels in place and finish the appearance of the celing

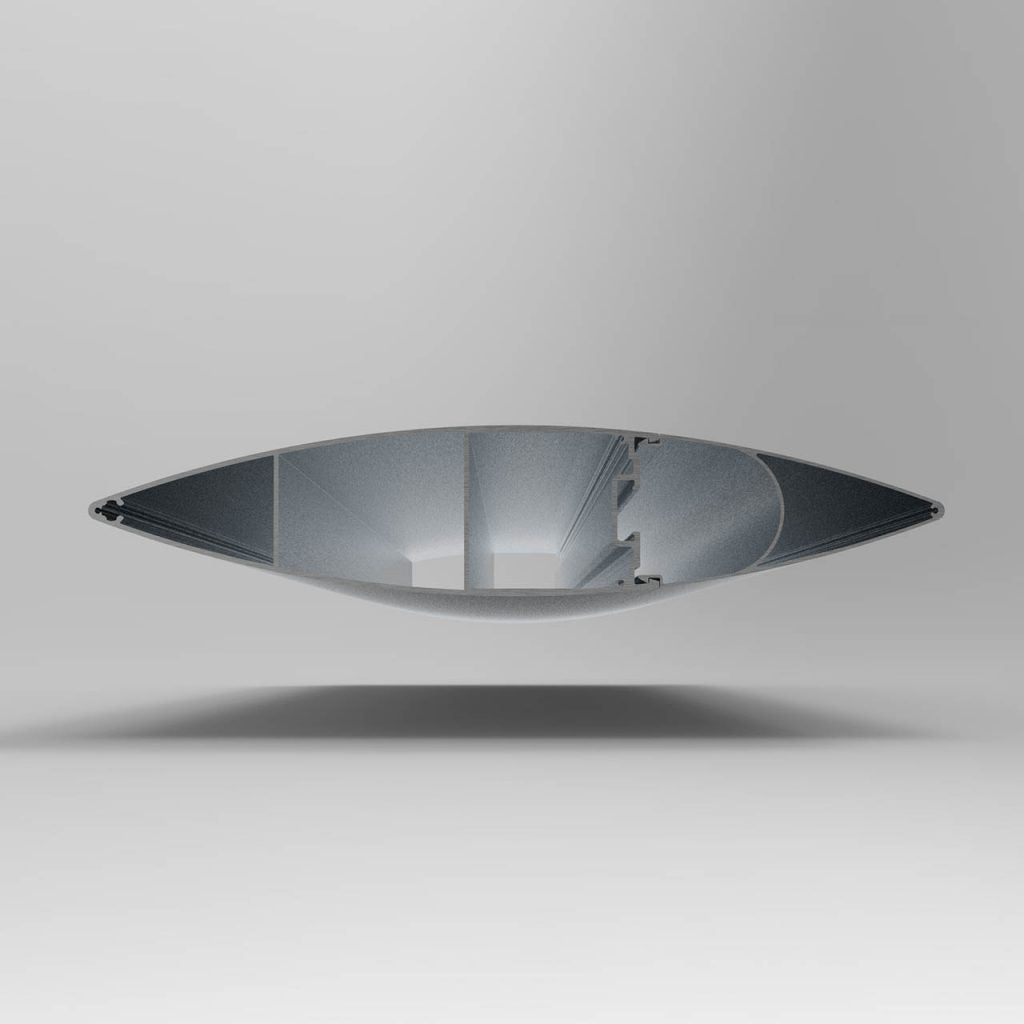

CREATING QUIET SPACES WITH SMART CEILING SOLUTIONS

An improvement to sound cantrol for an acoustic celing system consists of perforated metal anels with acoustic backing matera.Echo and noisereduction makeitnot only functionacoustically but also with a sleek, modern architectural look.

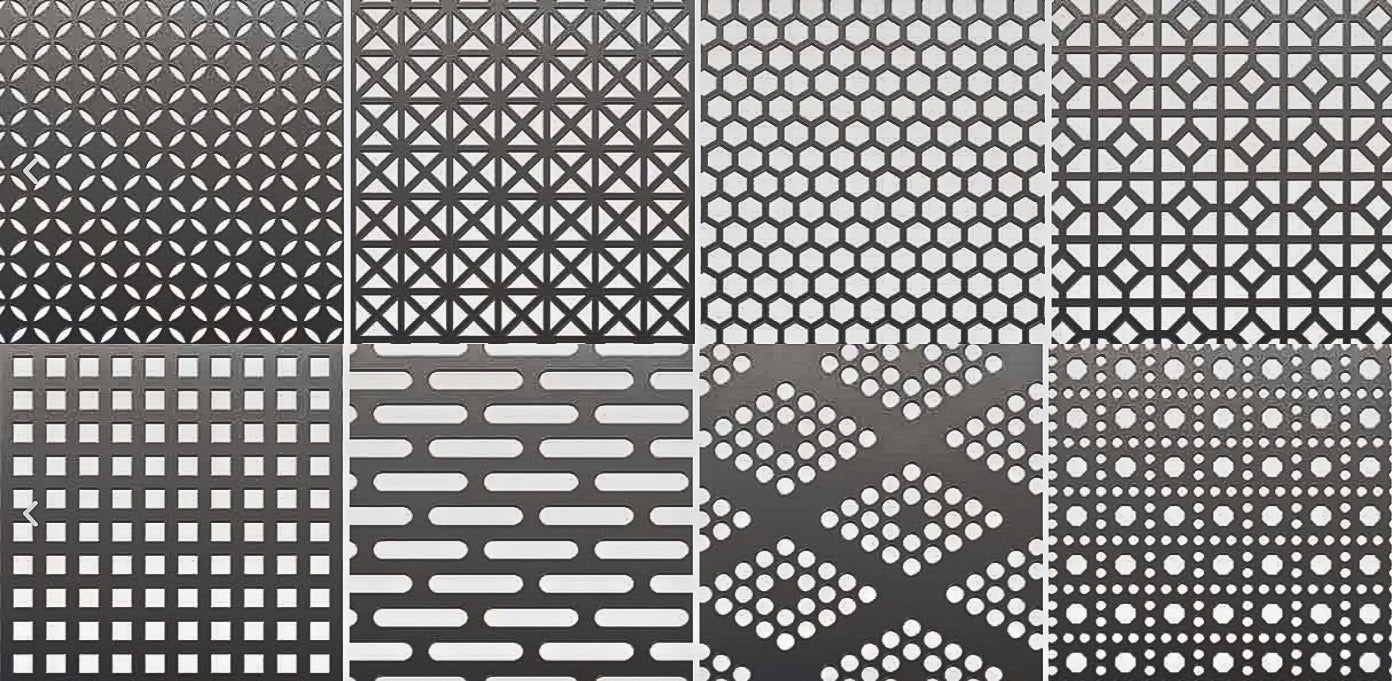

Perforated Metal Panels

The metal celing panels are precision pertorated in roung, sauare, sioted,or custom patterns, Sound that passes throuph these openings instead ofboundine off the roomdissipates sound energy, making less bounce and echo in the room.

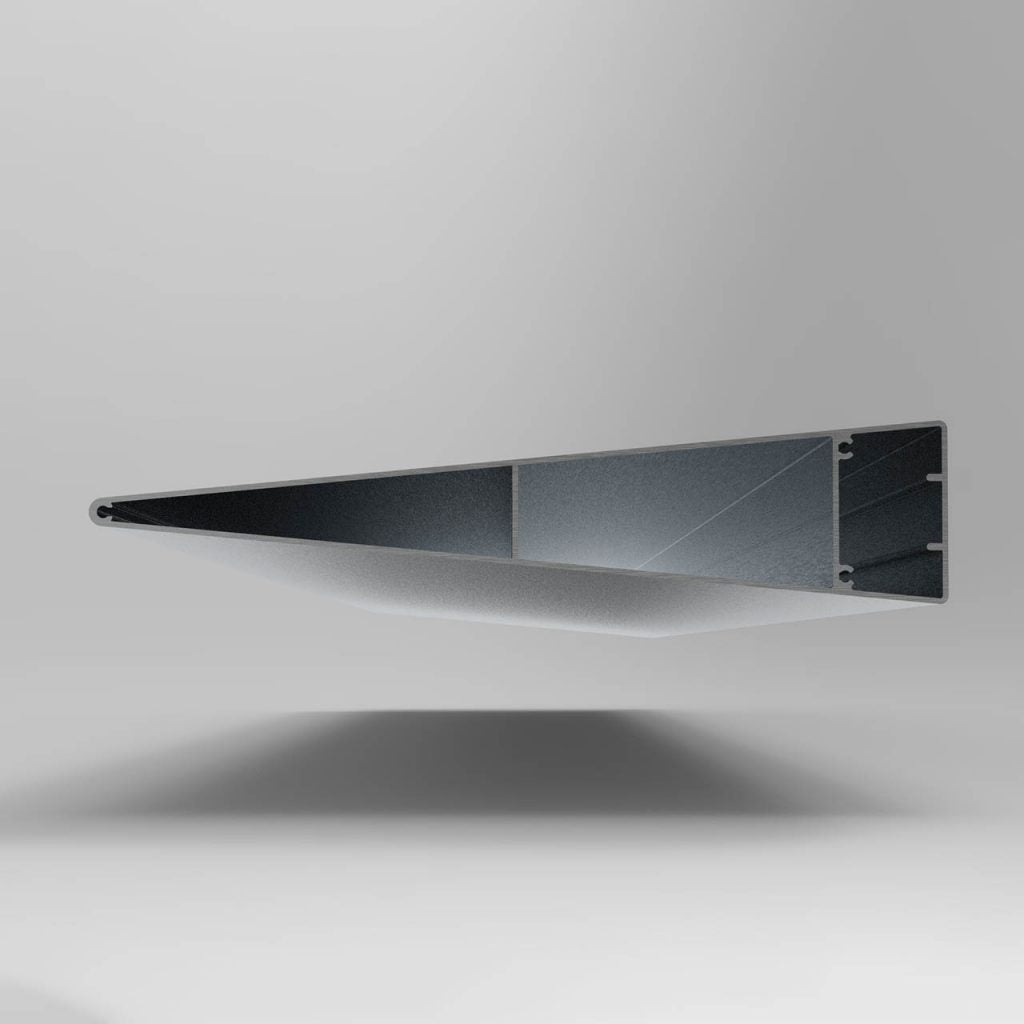

Baffle Ceiling

Baffle Ceiling is one of PROLINE’s most established products. The aluminum baffle ceiling system can seamlessly integrate lighting fixtures, creating distinctive light and shadow effects that enhance interior visual appeal. With advantages in aesthetics, sound absorption, durability, and design flexibility, metal baffle ceilings are a preferred choice for commercial and public spaces.

Performance profile

- Up to 0.50 (class D)

- 0.90 with acoustical pad (class A)

A2-s1,d0 (pre-painted steel)

Not available

Only interior

Not available

Baffle Shape

- Maximum Length: 5000 mm

- Maximum height: 150 mm

- Function:Fireproof, Moisture-Proof, Mould-Proof, Soundproof, Waterproof

- Surface:Powder coating; Per-paint

Perforated Ceiling

PROLINE perforated ceilings, made from premium aluminum, feature precision perforations that offer both decorative appeal and excellent acoustic performance. With surface options such as powder coating, anodizing, or wood grain finish, they are ideal for commercial, office, and public spaces in Queensland, meeting developers’ needs for aesthetics, functionality, and durability.

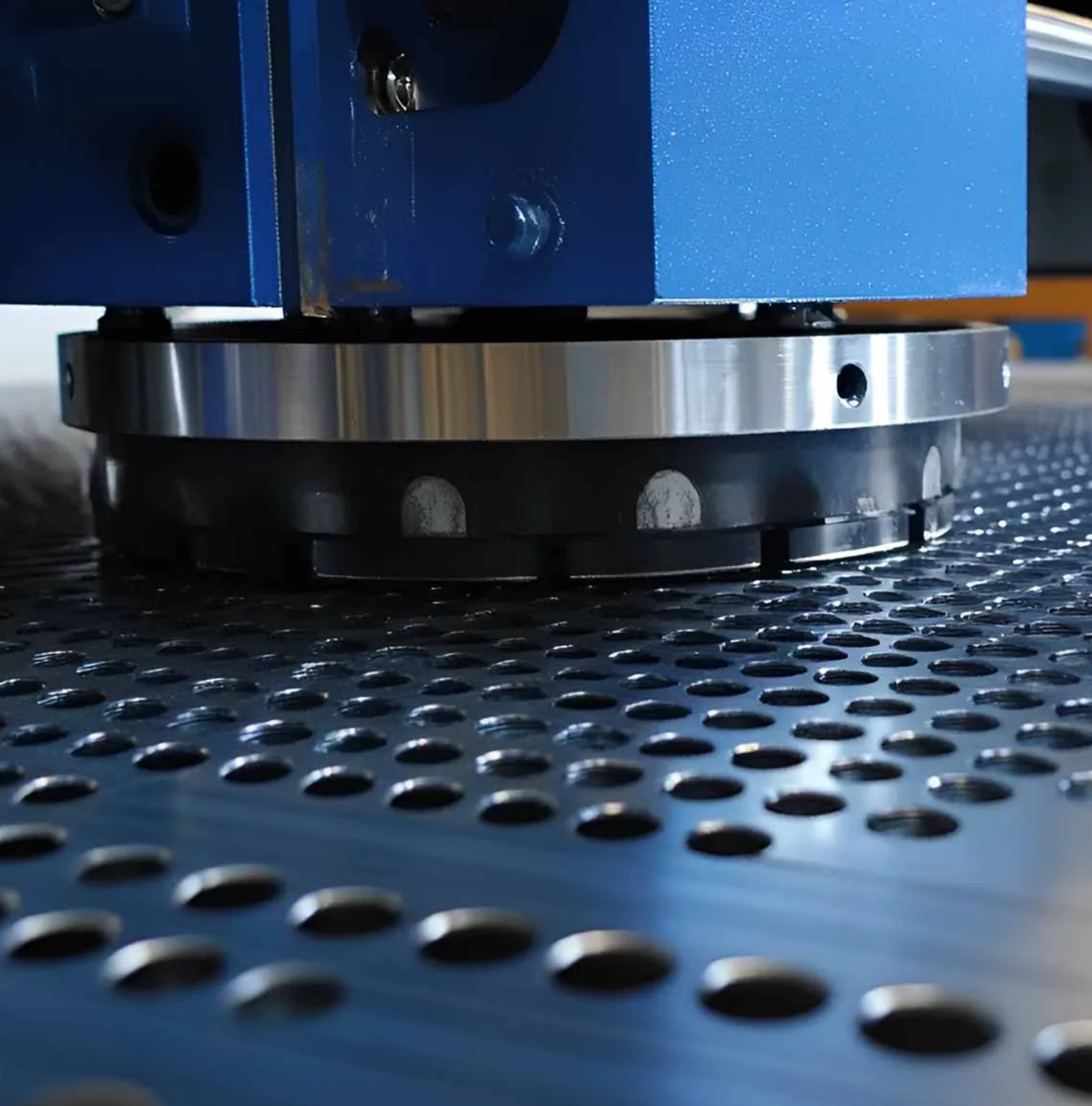

Processes Of Making Perforated Metal Ceiling Panels & Tiles

In interior design, we can find perfarated metal celing tiles or panelsthathave several paterms andacousticbenets.Do you want to find outhow they are made? ome along to se the stepsbehind these gorgeous creations, unique to this project.

Design Conceptualization

This section with celing tles made of perforated metalbegins with unique paterms that adoptaesthetics, function, androom themes, Designers play with shapes and sizes toachieve striking visuals and to perfect sound quality in the design impact.

Material Selection

Versatle aluminum, cassic coper and durable stainless steel are just some ofthe materials used for perfrated metal celing panels.Al options strike a perfec balance betweenstrength and aesthetic appeal to allow designers fulfill their vision.

Perforation Pattern Design

The paterm of the surace ofthe metal ceing afects the viswaland the acoustical perormance,Thelr advanced alporthms are shaped into stuctures that maxmize hole densitnfor perfect light diffusion, sound environment in buildings and heat flow.

Precision Perforation

Once isues are worked out and the design is readv to go, hole making can begin. Particular visualand acustic efects are achieved precisely with modern high-tech,computercontrolled machinery with exact hole diameters, patterns and spacings.

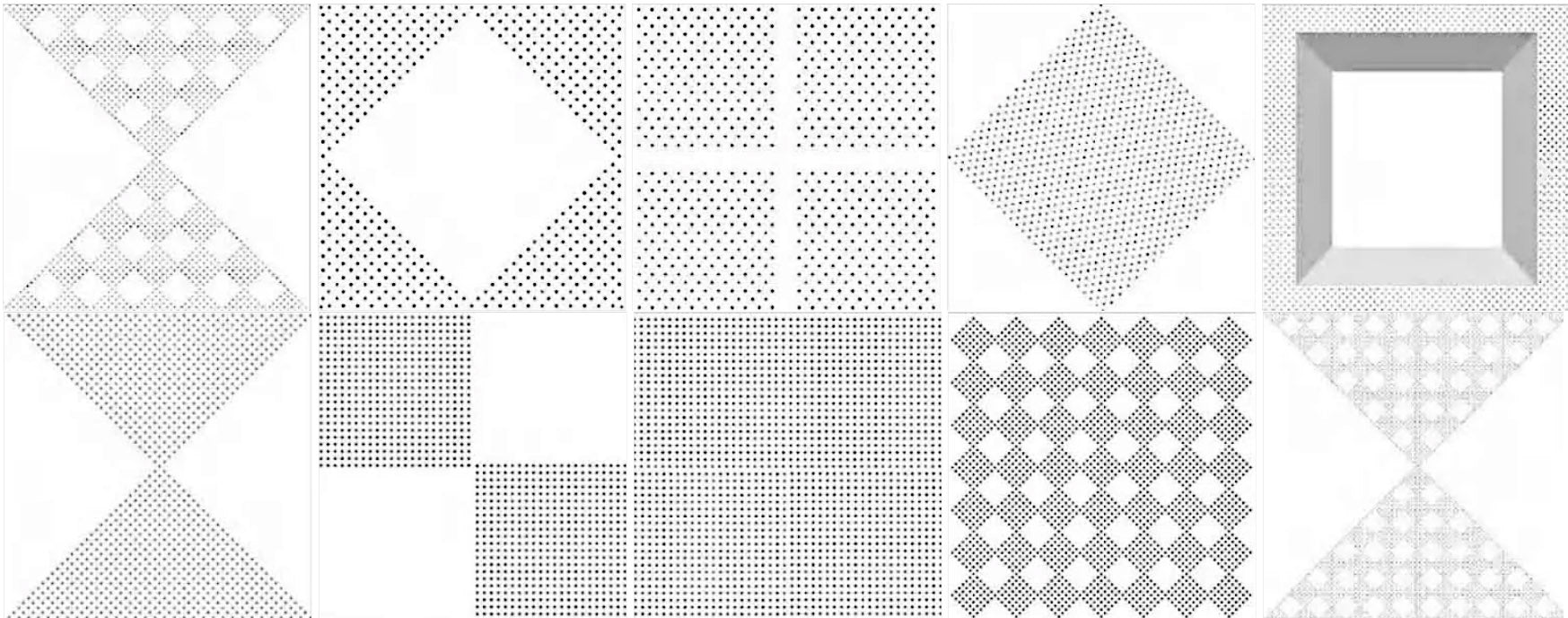

Perforation Arrangements for Metal Ceilings

Hole Shapes

Most businesses use perforaionsthat come in round, square and sloted shapes, plus designs prefered by their ients, The style of the roof should be specialand the ventilationsystem has to work, so the plan must achieve both these points.

Hole Sizes and Spacing

Depending on the hole diameter and its istancefrom the next one, you canimpact the way light, ail, and nise travel in your home. Thanks tothese special features, perforatedceilings can fulfill the requirements of any area for function as well as design.

Custom Designs

How far the perforated holes are apart and the diameter you choose wil decide the direction of sound,ai movement and sunight. Thanks to the various perforations,perforatedceilings work in any area for both functionality and design.

FAQ

Explore key questions about our aluminium facade systems, including product types, compliance, and design flexibility—tailored for residential and commercial projects across Queensland.

What are the common surface finishes for aluminum ceilings?

Common finishes include powder coating, anodizing, and wood grain transfer, with corrosion-resistant options recommended for Queensland’s climate.

Do aluminum ceilings provide sound absorption?

When designed with perforations and paired with acoustic insulation, aluminum ceilings can significantly improve indoor acoustics by reducing echo and noise.

What factors should developers consider when choosing aluminum ceilings?

Developers should consider space functionality, acoustic needs, climate conditions, and aesthetics, while choosing a supplier with customization capability and installation expertise.