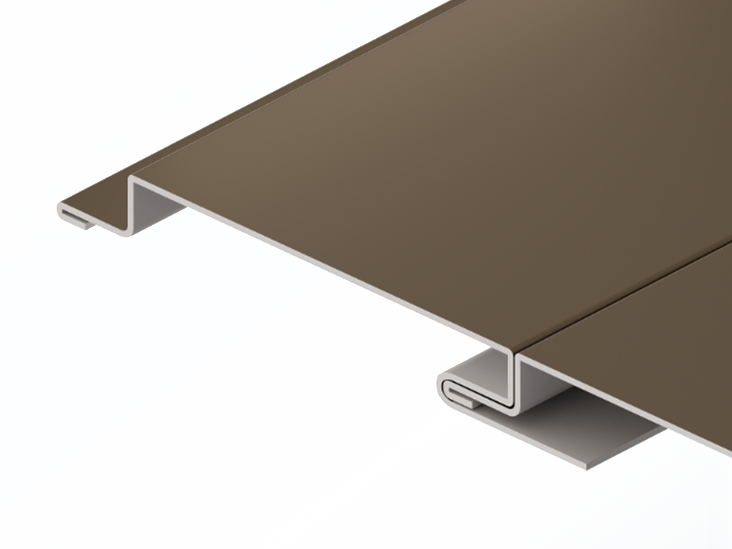

Flush

Combining modern aesthetics with a refined look, Metal Wall Panels bring unique style to interior spaces. They fuse functionality with visual appeal, offering a durable solution for commercial and residential environments. Resistant to dampness, corrosion, and other factors, they ensure long-lasting performance.

Flush Panels are engineered to meet modern construction standards, reducing air leakage per ASTM-E283 for better energy efficiency, resisting high wind loads per ASTM-E330, and preventing water penetration per ASTM-E331. They also meet ASTM-E84 fire safety standards.

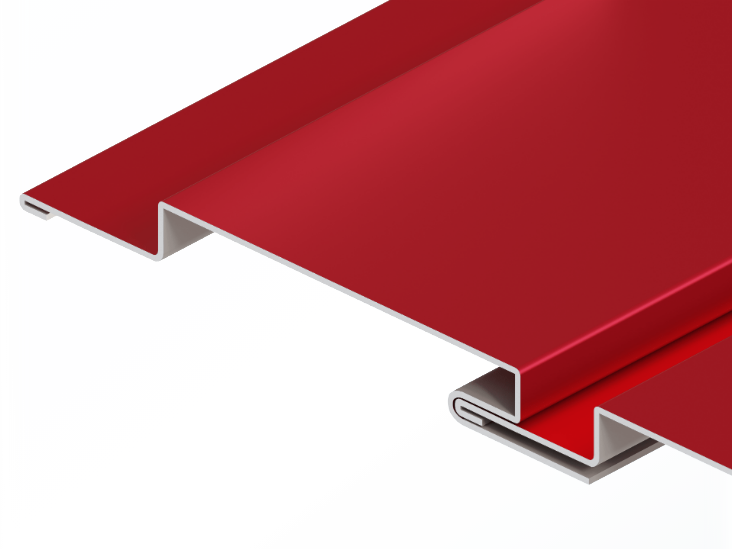

Flex Reveal Panels meet multiple standards: ASTM-E283 for reduced air leakage, ASTM-E330 for structural stability, ASTM-E331 for water resistance, and ASTM-E84 for fire safety.

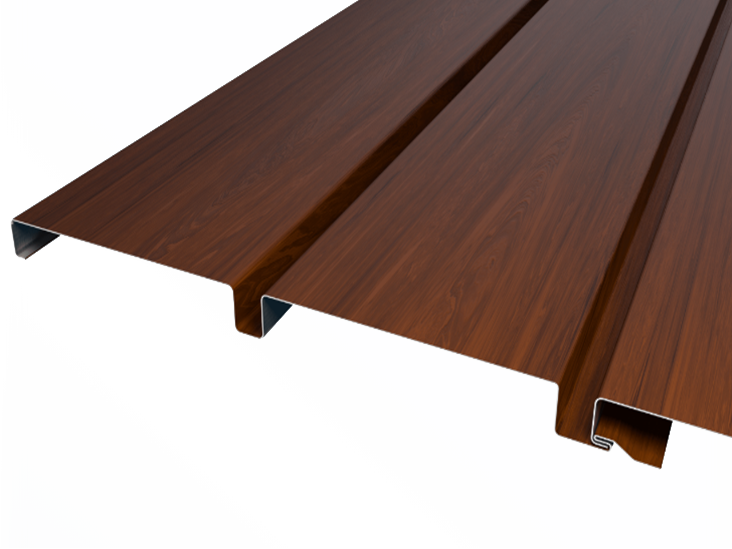

Double Plank Flush Panels provide a multi-seam look without extra fasteners, offer excellent structural stability, and are fully customizable to meet diverse interior design needs.

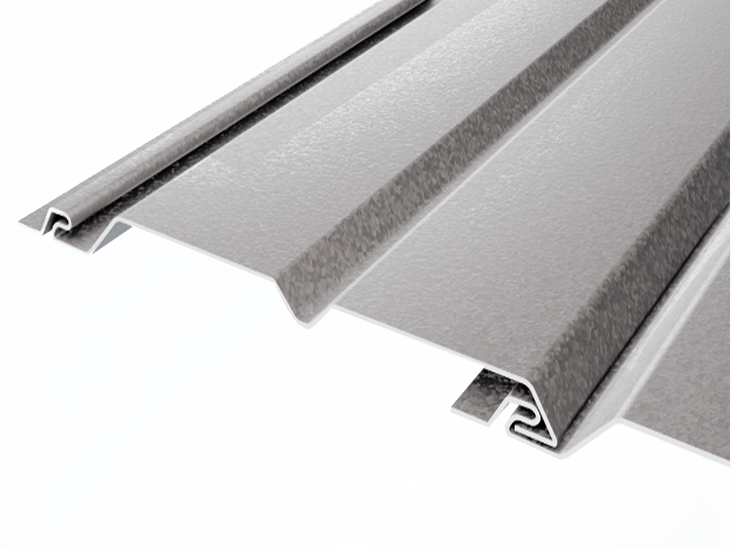

V-Groove Soffit Panels feature a concealed fastener design for a sleek, modern look, are fully customizable to meet specific design needs, and combine aesthetics with functionality for a clean finish, durability, and strength.

Perforated

Perforated interior wall panels offer a modern decorative solution with acoustic control, ventilation, and integrated lighting possibilities. Made from durable aluminum, the perforations create unique light and shadow effects, enhancing ambience in offices, retail spaces, and public interiors.

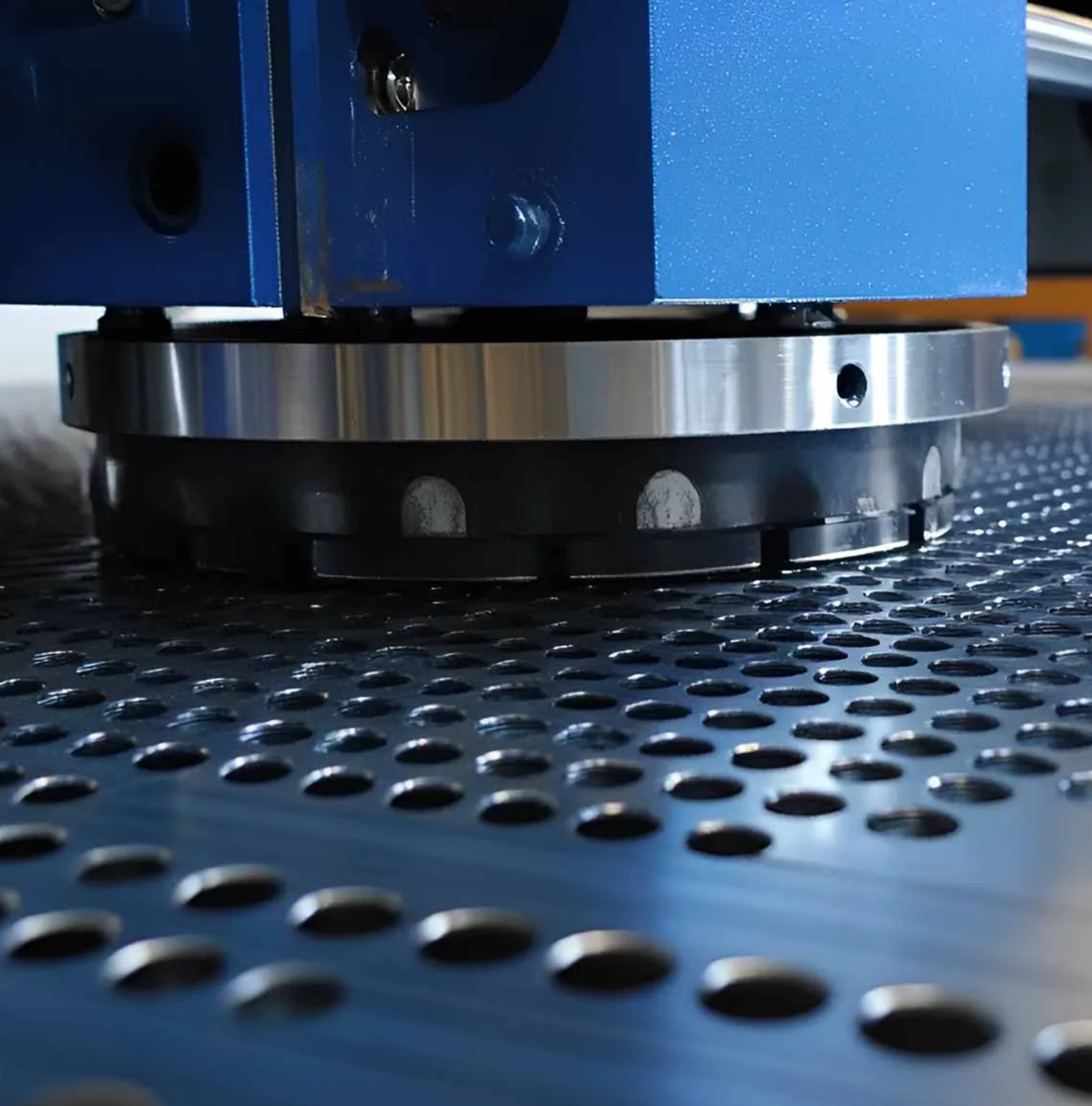

Processes Of Making Perforated Metal Ceiling Panels & Tiles

In interior design, we can find perforated metal wall panels that feature various patterns and acoustic benefits. Do you want to find out how they are made? Come along to see the steps behind these gorgeous creations, unique to this project.

Design Conceptualization

This stage with wall panels made of perforated metal begins with unique patterns that combine aesthetics, function, and room themes. Designers play with shapes and sizes to achieve striking visuals while perfecting sound quality and overall design impact.

Material Selection

Versatile aluminum, classic copper, and durable stainless steel are just some of the materials used for perforated metal wall panels. All options strike a perfect balance between strength and aesthetic appeal, enabling designers to fulfill their vision.

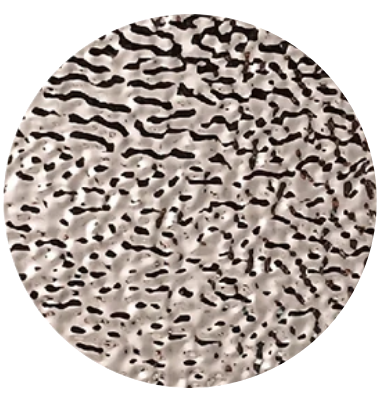

Perforation Pattern Design

The surface pattern of the metal wall panel affects both the visual effect and acoustic performance. Advanced algorithms are applied to create structures that maximize hole density for optimal light diffusion, sound control, and heat flow in interior spaces.

Precision Perforation

Once the design is finalized, the perforation process begins. Specific visual and acoustic effects are achieved with modern high-tech, computer-controlled machinery, ensuring precise hole diameters, patterns, and spacings.

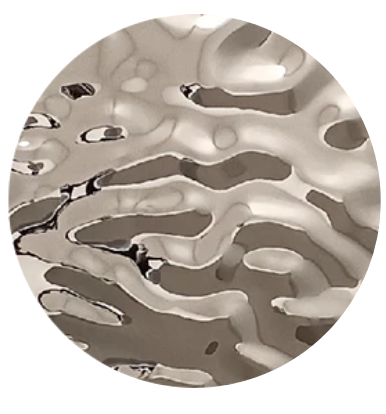

Water Ripple

Stainless Steel Water Ripple Panels offer excellent corrosion and high-temperature resistance. With polished, brushed, or other finishes, they deliver enhanced visual appeal and wear resistance. The wavy texture adds beauty while effectively hiding scratches and dirt. Suitable for indoor and outdoor use, they feature high strength, impact resistance, and an easy-to-clean smooth surface.

Specification

- Width: 1.5~4m

- Length: 1.5~4m

- Thickness: 0.6~1.2mm

- Surface Color: Original color

- Material: 304 steel, 304L steel, 316 steel

FAQ

Explore key questions about our aluminium facade systems, including product types, compliance, and design flexibility—tailored for residential and commercial projects across Queensland.

What are the common surface finishes for aluminum ceilings?

Common finishes include powder coating, anodizing, and wood grain transfer, with corrosion-resistant options recommended for Queensland’s climate.

Do aluminum ceilings provide sound absorption?

When designed with perforations and paired with acoustic insulation, aluminum ceilings can significantly improve indoor acoustics by reducing echo and noise.

What factors should developers consider when choosing aluminum ceilings?

Developers should consider space functionality, acoustic needs, climate conditions, and aesthetics, while choosing a supplier with customization capability and installation expertise.